Mass Finishing | HR Combo

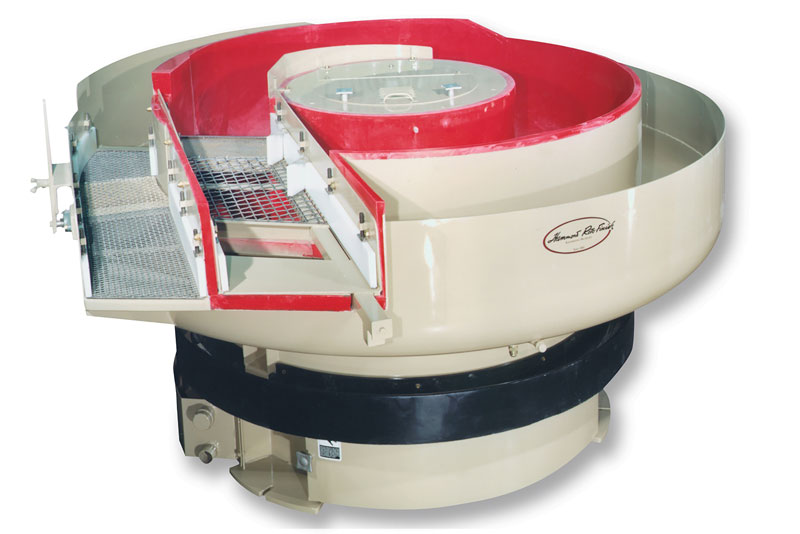

HR Combo

The HR Combo Series features the same tankhead design as the HR Series machines, the outer tankhead is the chamber for parts drying. This structure utilizes the same tank head design for structural integrity. The addition of the second chamber to the outside of the process area reduces costs and floor space. With unload gates available for both the processing and drying channel, this is one of our most versatile machines.

– One Drive System

– One Machine that Processes & Dries Parts

– One Electrical Panel

– Smaller Footprint

Features

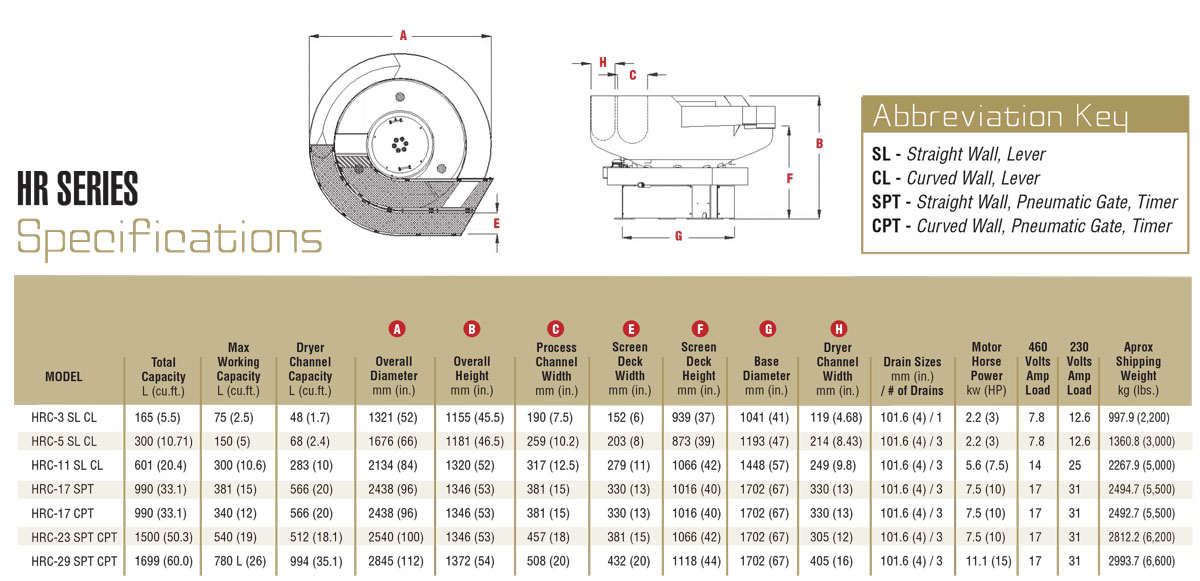

Specifications

PDF

Photos

Videos

Features

- Heavy Duty Welded Steel Construction

Main building component of the bowl is 1/2″ thick pressure vessel material. - Cast Polyurethane Liner

Polyurethane liner is cast, not sprayed on. This improves media rebound and provides more wear depth. 50% additional lining in high wear areas. - “U” Shaped Straight or Curved Wall Processing Bowl

- Full 90º Wrap-Around Separation Screen

- Cartridge Drive System

Features adjustable top and bottom eccentric weights. Drive exchange program with in-stock availability. - Premium Efficiency T-Frame Motor 230 or 460/3/60 Specify 230 or 460 volts. Motor is mounted to non-vibrating base. Belt drive to main shaft for 1,250 V.P.M.

- Water-Driven Compound System

- Heat Lamp(s), with Control Panel Mounted Controls

Specifications

PDF

Click to Download PDF

Photos

Videos